Brewing Yeast Management

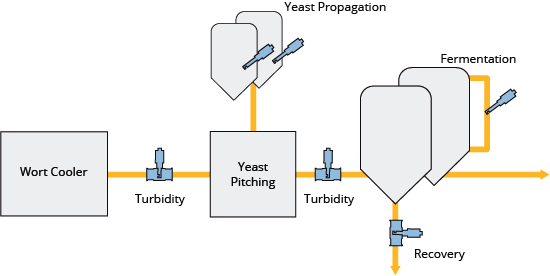

Yeast PitchingYeast dosing can be done precisely and inexpensively using a technique called differential NIR absorption. This method uses two sensors. The first or upstream sensor is a single channel, NIR absorption based AS16-VB-N photometer used to “baseline” the wort turbidity.

optek Products used in Brewing Yeast Management

This sensor often can double as a whirlpool outlet monitor, or a cold break monitor, depending on its location in the brewhouse. The downstream AS16-VB-N sensor would be located after the yeast injection point, prior to any air injection. This sensor measures the combined yeast and wort stream. Simply subtract the baseline result from the combined stream result to get pure injected yeast content.

With a simple comparison to the yeast lab cell count method, the correlation to cell count can be programmed directly in the C4000 converter and displayed simultaneously. Multiple strains with different absorption / cell count ratios can also be accommodated by using additional product configurations. There are a total of eight product definition set-ups available.

Correlation of Absorption to million cells/mL

NIR absorbance is directly proportional to the concentration based on Lambert-Beer’s Law. Correlations to cell count are easily done with any repeatable laboratory method. Multiple product functions in the C4000 allows multiple correlations for different yeast strains if required.

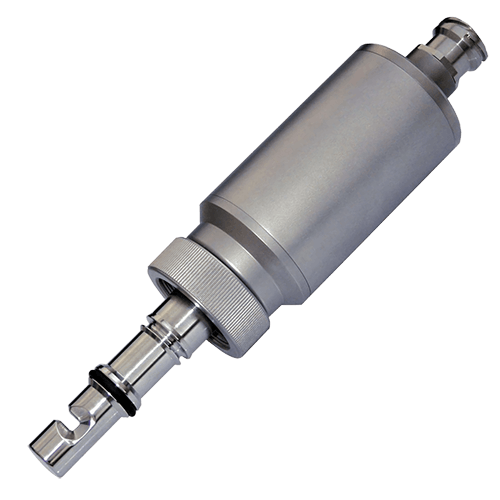

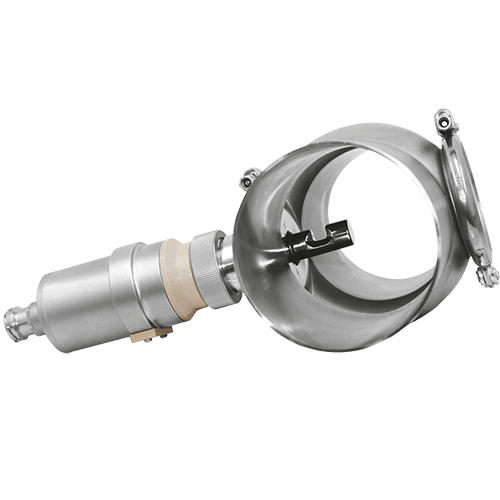

optek AS16-VB-N Single Channel Absorption Probe with Calibration Adapter

optek C4000 Photometric Converter

Yeast Fermentation

In yeast fermentations, AS16-VB-N probes have the unique ability of mounting directly in the fermentation vessel or directly in a bypass line via different adaptors. Properly located, the entire fermentation cycle can be monitored in real-time, allowing optimization of the process. Tanks can be released automatically rather than waiting hours for lab samples to indicate proper yeast flocculation. Feedback on any recipe influences of yeast cell growth can also be seen. In larger cellars, saving 6-10 hours per fermentation cycle can add up quickly, adding valuable fermentation capacity, without adding a single fermenter.

Beer / Yeast Interface, Yeast Recovery

Many breweries are using large vertical fermenters or multi-purpose tanks. One of the main advantages of these tanks is avoiding extra product transfers. However, settled yeast must be removed. A turbidity sensor is installed in the tank outlet, or in the yeast harvest line. When the yeast is removed from the beer the turbidity meter will determine the interface between the yeast and beer. In the past this was accomplished by time / volume or visual inspection. Since the set points are adjustable the optimal cut-off level can be obtained to provide the most efficient operation. This reduces product loss and provides a more uniform product for separation or filtration.

Beer / yeast interface and yeast harvesting also typically uses the AS16-VB-N inline sensor. However, for basic interface applications, where the interface detection is the only objective, optek offers a lower cost probe style sensor in the AS56-N. Its lower power lamp module also allows up to four AS56-N series probes to be multiplexed in one C4000 based system, thus making the measurement point cost even more attractive.

optek AS16-VB-N Single Channel Absorption Probe with Calibration Adapter

Get in Touch with optek

If you have any further questions or queries please do not hesitate to get in touch.