Chlorine Dioxide Vent Scrubber Monitoring

ClO2 Solution StrengthIn chlorine dioxide generation, gaseous chlorine dioxide is transferred to the absorption tower and dissolved in chilled water to yield the strong aqueous chlorine dioxide bleach solution.

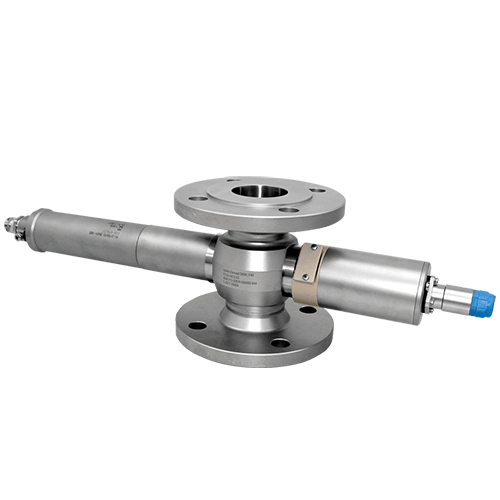

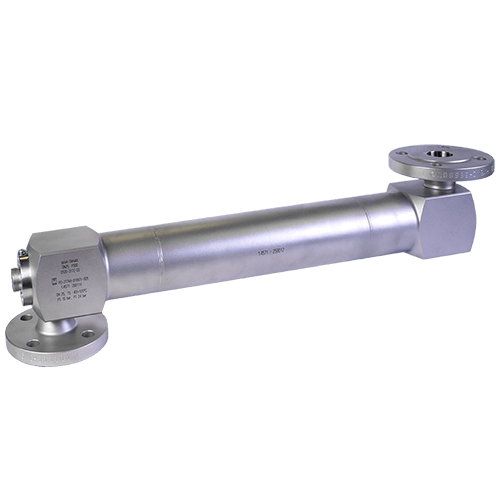

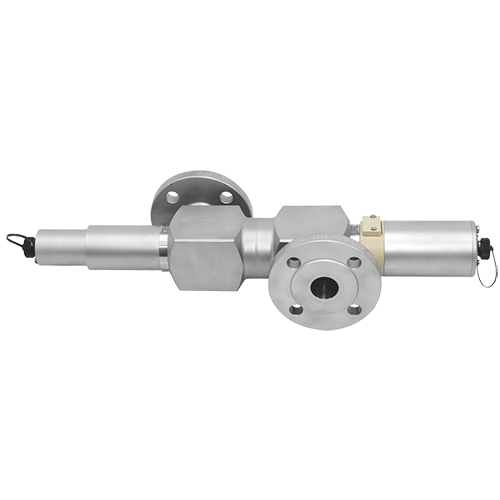

optek Products used in ClO2 Vent Scrubber Monitoring

This solution is then pumped to storage tanks for further use in the pulp bleaching process. To ensure optimum control of the ClO2 bleach solution strength, ClO2 concentration is measured before and after the storage tanks using an optek AF26 dual channel absorption sensor.

Typical range: 0 - 15 g/l

ClO2 Generator Gas Concentration

In addition to the ClO2 concentration measurements, using an AF26 sensor to measure the ClO2 generator gas concentration at the inlet of the absorption tower helps optimize the ClO2 generation process.

Typical range: 0 - 20 % Volume

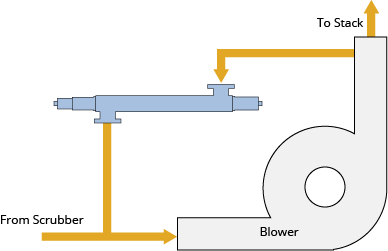

ClO2 Vent Scrubber Monitoring

Vent gases are combined and sent to a wet gas scrubber where white liquor or weak wash is used as a reducing agent. The scrubbed vent gases are then transferred to the stack for discharge. For environmental control, residual chlorine dioxide measurements in the vapor phase are employed to reduce chlorine dioxide emissions and control vent-gas scrubbers. Installing an optek AF26 inline chlorine dioxide sensor in a side loop off the stack allows for real-time chlorine dioxide concentration measurements.

This provides plant personnel an immediate indication of a scrubber malfunction along with ensuring environmental compliance and helping operators optimize the dosage of white liquor or weak wash into the scrubber.

Typical range: 0 - 500 ppm

optek AF26-EX-HT-VB Dual Channel Absorption Sensor

Get in Touch with optek

If you have any further questions or queries please do not hesitate to get in touch.