White Liquor Filtration

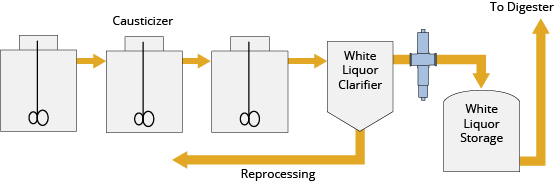

FiltrationIn the causticizing process white liquor is filtered and clarified to remove particulates and lime mud. These can create long-term scaling problems at the digester and downstream problems due to contamination. Installing a turbidity sensor after the white liquor clarification process allows for immediate detection of high solids levels in the white liquor. These high solids levels can be a result of either a filter break or poor settling in the clarifier.

optek Products used in White Liquor Monitoring

Measurement Range

Proper clarity of white liquor prior to storage can be verified by using an optek TF16-N scattered light sensor with sapphire optics that are resistant to hot caustic process solution. Maximum measuring range is 0 to 500 ppm for this application and the optimal used range is 0 to 100 ppm with a normal lime mud content of less than 20 ppm.

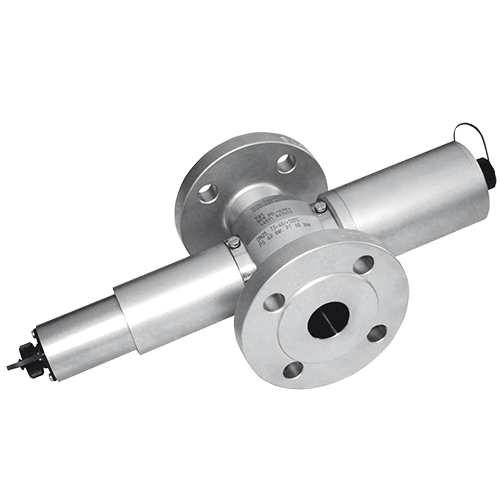

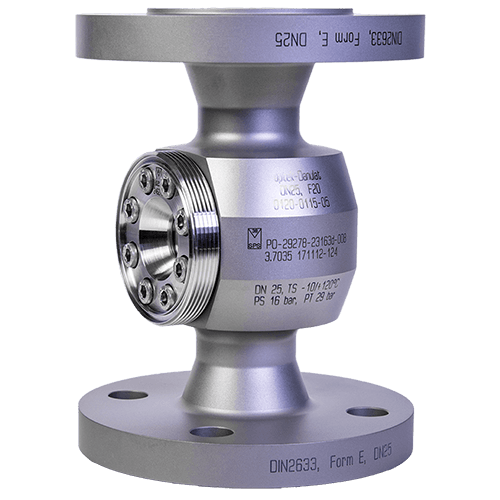

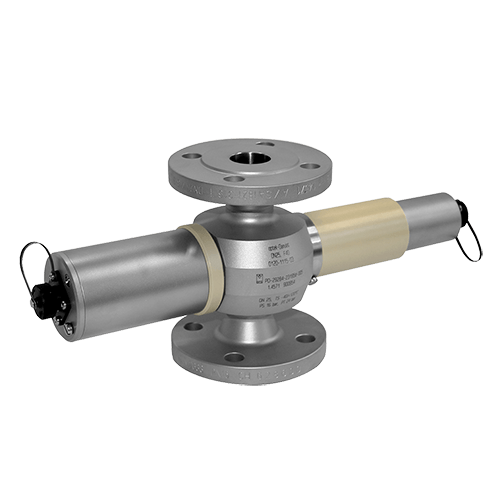

optek TF16-N Scattered Light Dual Channel Turbidity Sensor

Benefits

Achieving high quality white liquor and increasing digester performance leads to reduction of product losses and lime build-up downstream. This, in turn, reduces overall maintenance costs in chemical recovery.

optek C4000 Photometric Converter

Get in Touch with optek

If you have any further questions or queries please do not hesitate to get in touch.