Filtration

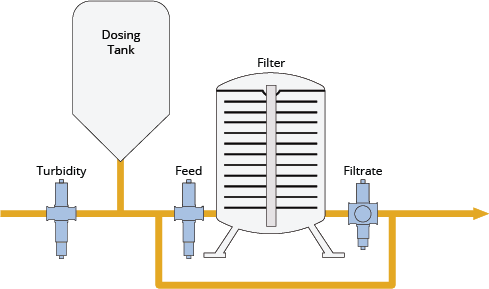

Filtration Control 11°/90°The optek Haze Control / DTF16 relies on a dual angle scattered light measurement for precise quality control during final filtration independent of color and color changes. Using this sensor downstream of the filter detects filter breakthroughs, preventing “out of spec” product while ensuring product quality and clarity at each filtration step.

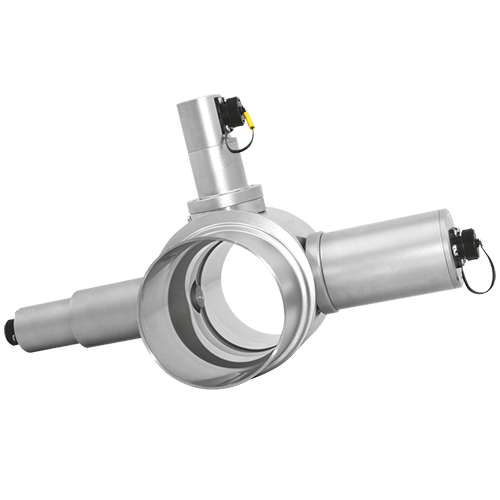

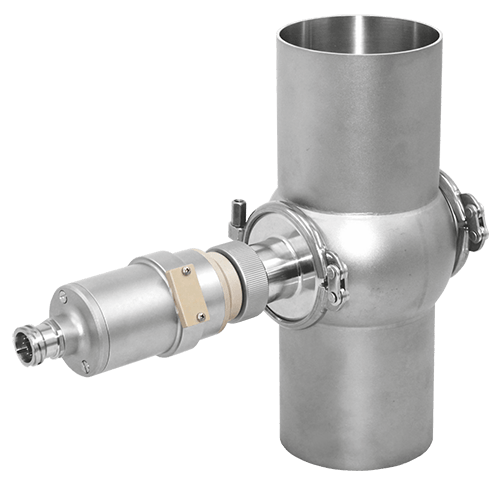

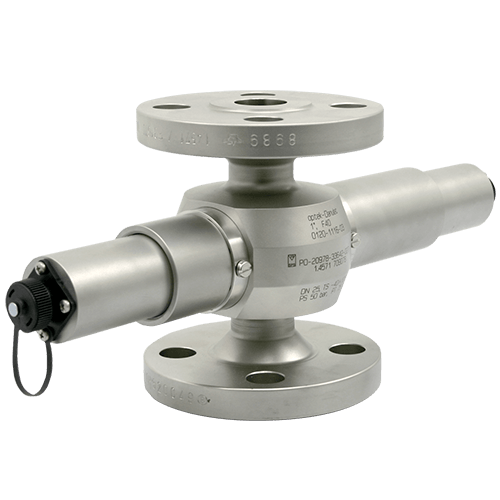

optek Products used in Filtration

Typical Applications:

Edible Oil:- Filtering of nickel catalyst for reuse, (turbidity measurement)

- Monitoring of the filtrate stream for turbidity

- Monitoring of filtration and stabilization

- Monitoring of filtration

- Monitoring filter breakthrough and clarity

Factory Calibration

Each optek DTF16 is factory calibrated to FTU standards which correlate to EBC, ppm (DE), ASBC or others.

Feed Monitoring

Using an optek AS16-N or AF16-N, the turbidity in the feed line can be monitored, allowing precise feed control while preventing filter clogging or blinding. This additional sensor can be connected to your Haze Control / DTF16 system without the need for an additional converter.

Filter Backwash Optimization

The optek AS16-N or AF16-N used for feed monitoring can also be used to optimize your filter backwash process by measuring the turbidity in the water, saving time, energy and conserving water usage.

optek Haze Control DTF16 System

Filter Aid Dosage

Dosage of filter aids like diatomaceous earth (DE) can be controlled with optek absorption or scattered light sensors. Optimizing filter aid usage reduces costs and ensures consistent product quality.

Filter Setup Monitor

Using the reference channel allows measurements at higher turbidity levels to monitor and control the filter pre-coat cycle.

Get in Touch with optek

If you have any further questions or queries please do not hesitate to get in touch.