Color and Concentration

Color MeasurementsColor measurements of liquids are critical in maintaining precise process control and meeting product quality specifications. Color changes indicate other process variables such as overheating, change in dilution ratios, the presence of dissolved impurities and finished product appearance. Typically, process color measurements are made by taking samples from the process piping and analyzing them in a lab either visually or using a laboratory analyzer. optek colorimeters provide precise, real-time color change detection directly in the pipeline.

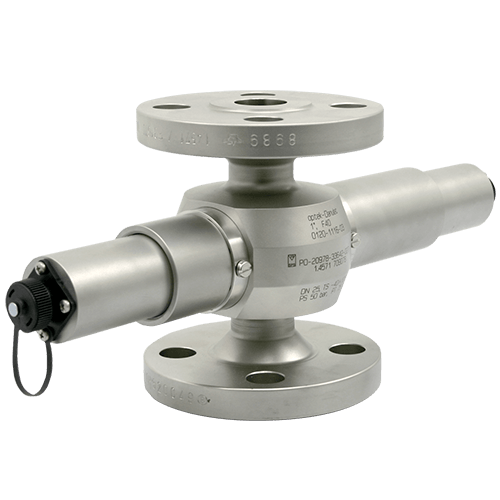

optek Products used in Color and Concentration Measurements

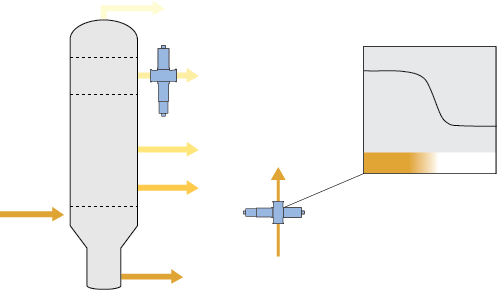

Color measuerments are achieved by passing focused light from the sensors lamp, through the process medium, to the sensors detector. As the light interacts with the process medium, some of it is absorbed, thus changing its intensity. The amount of light absorbed, which is wavelength and optical path length (OPL) dependent, will then be an indicator of color or color change.

Changes in light absorbance, due to changes in color, are monitored by the detector in the sensor and a signal is sent to the C4000 converter. The C4000 converter correlates the changes in absorbance to a color scale such as APHA/Hazen, ASTM, Saybolt or others and generates a signal to a PLC or DCS, using analog outputs, Profibus PA® or FOUNDATION™ Fieldbus. The C4000’s local, real-time display allows operators immediate access to ongoing process parameters.

Concentration Measurement

The measurement is represented in Concentration Units (CU) at a given wavelength with a defined optical path length (OPL) and relates to the concentration of the constituents in question that interact with the light.

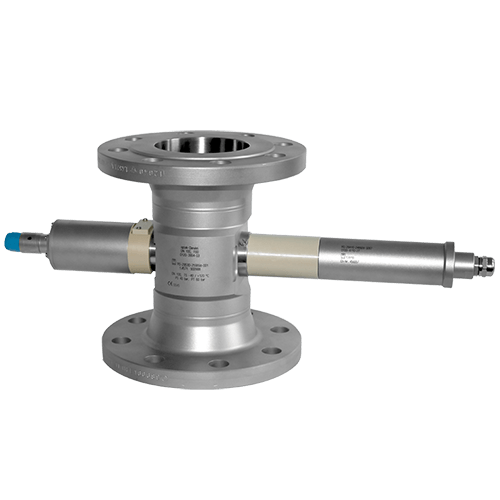

optek AF26-EX-HT-VB Dual Channel Absorption Sensor

Typical Applications

- Color scales (APHA / Hazen / Pt-Co, ASTM D-1500, Saybolt, Gardner® and other scales)

- Concentration of chlorine dioxide

- Transition metals (nickel, copper, chromium, iron, cobalt, manganese)

- Color dosing and decolorization control

- Leak detection/carryover

- Product interface and dosing/blending control

- Distillation control

- Quality control in solvents / epoxy resins (APHA / Hazen / Pt-Co, ppm iron)

- Concentration measurements of colored additives and catalysts (e.g., iron in HCl)

- Galvanic plating operations (nickel plating)

- Copper sulfate concentration in copper foil manufacturing

- Water/solvent ratio measurement

- Hypochlorite concentration

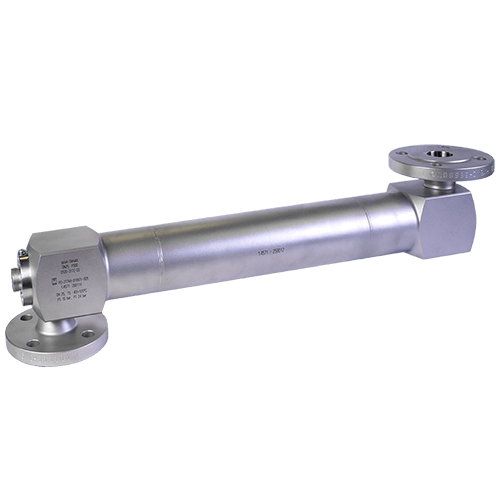

optek C4000 Photometric Converter

Process Optimization

The detection of impurities, reduction of product losses and the real-time assurance of product quality can be obtained by the use of inline colori-meters. In addition, these analyzers greatly reduce laboratory and production costs, eliminate human error and prevent environmental contamination.

Get in Touch with optek

If you have any further questions or queries please do not hesitate to get in touch.