Brewhouse Turbidity

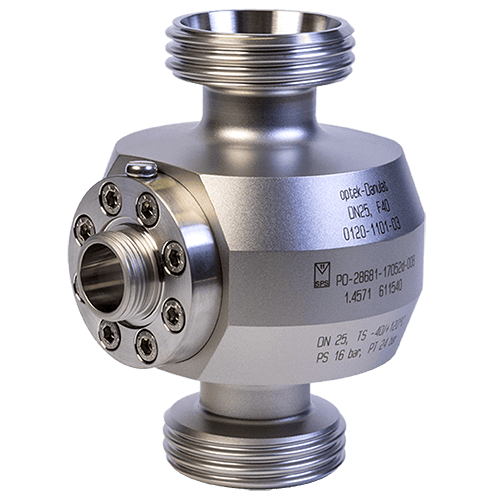

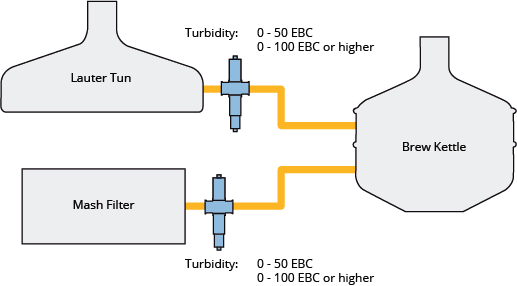

Wort Clarity MonitoringLauter tun run-off clarity, has traditionally been a hands-on monitoring operation performed by brewery personnel; however, this is now commonly done with a TF16-N scattered-light turbidity meter.

optek Products used in Brewhouse Turbidity

The measuring ranges depend on the clarity levels reached and on measurement expectations. This turbidity meter continuously monitors solids concentrations in the extract stream to automatically indicate a switch to flow forward to the brew kettle when the desired clarity level is achieved.

More importantly, it can automatically react to any husk bed upsets or elevated solids concentrations due to bed cuts. While in forward flow mode, this measurement result can be read in EBC, ppm (mg/L) or be correlated to % TSS (total suspended solids), which can then be combined with flow data to create a flow weighted average of total solids transferred. Control of the wort production process offers predictable downstream solids content for both operational efficiency and flavor / clarity stability.

Mash Filter Monitoring

Using a mash filter for clarifying the wort makes the turbidity measurement even more important. Achieve better product quality by decreasing product losses and improving filter lifetime. Filter breaks can be immediately detected using a scattered light based TF16-N turbidity meter, to precisely monitor very low particle concentrations as well as a more broad turbidity range using the absorption signal simultaneously. Automated alarms will signal any filter breakthrough, while filter set-up times, throughput capacity and CIP cycle duration can be optimized.

optek TF16-N Scattered Light Dual Channel Turbidity Sensor

Get in Touch with optek

If you have any further questions or queries please do not hesitate to get in touch.